Trimmer type: Forslunds 300 delivered the 1998th

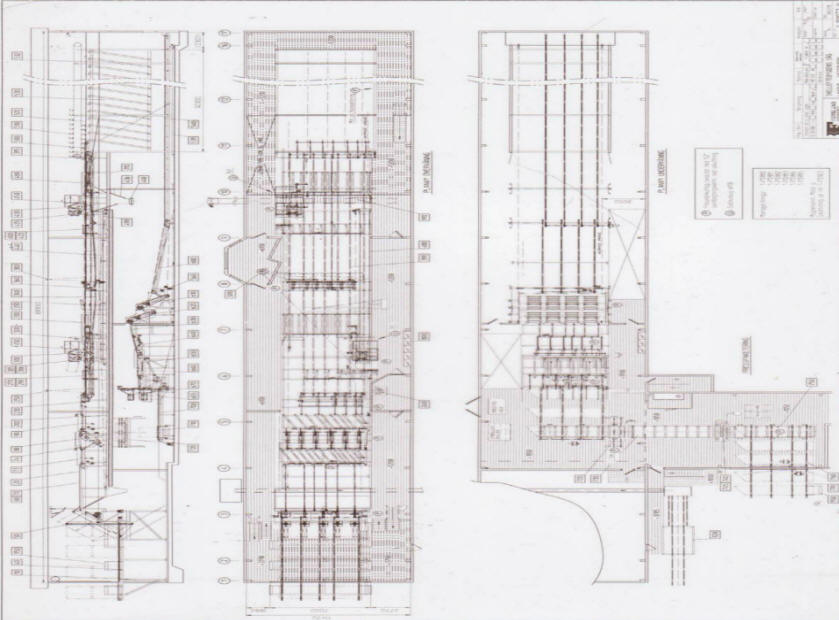

The timber destocking in Packages lift the scattering section in an even strata using the lift

leveling system. The elevator works out the timber and transport it to the operator site 1.

Rough lumber can let pass the elevator on a bypass to reduce noise and timber damage.

The capacity of the plank 50 x 125 is approx. 15 000 bit / shift and for boards approx. 16 000 bit / shift.

At the operator position 1 one piece fed wood and presented to the operator who decides where

cutting the root end should be. Hijacking occurs without contact via power allocation and mini trimmer.

After cutting the root end is the timber over to the operator 2 (possibly 3) and via LASER POINTER determines where saw cape the top end to occur and the quality of the finished piece has. To reduce the

dust and noise have avkapsanslag and mini trimmer placed in kalldel (fackdel).

The wood is then sorted into 30 pieces adjustable compartments. After the tray is empty the timber via a double

elevator section to the package installation and packaging. Timber Press is manufactured by GOLIATH

(automatic / CH + arcing automatic) recording and printing see Pronyx AB in Sundsvall.

Supplement

Building, stab, fuse box and everything else can also be included in the delivery